Like any good recipe, it needs to get tasted—tested—and refined. Collaborating with their corrugate manufacturer, chip manufacturer, tag provider, and tag reader provider, Golden State Foods was able to move the tag placement upstream to the corrugate process. By successfully streamlining tag placement at the source, the “pre-tagged” corrugate provided Golden State Foods the opportunity to make the recipe more palatable to suppliers.

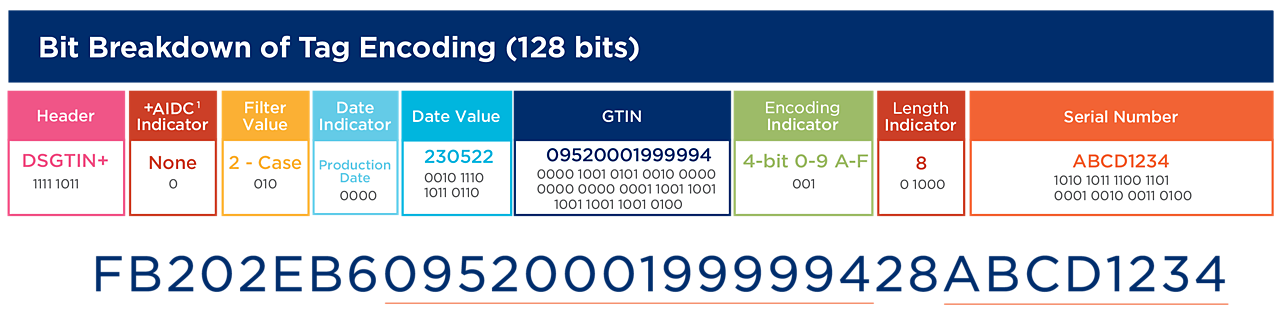

To validate those attributes, improve the traceability of their patties, and to test the ability for trading partners to access the data, they launched a pilot at their Opelika, AL, manufacturing facility. For Opelika operations, the production date is the lot-level information. By adding this additional ingredient, they proved that partial encoding in real time was plausible. After the date value was encoded onto the pre-tagged corrugate RFID label, it was locked to prevent any further code changes.

While this would be an important step to increase the precision of their end-to-end supply chain tracking as they achieved in their earlier proof of concept, the added steps could not impact operations or slow the speed of the line. Also, to keep costs the same, Golden State Foods didn’t want to change to high-memory RFID tags.

For this pilot, they started at the beginning of the line – incorporating steps for automatic verification and validation of proper encoding—all the way to post-production. After post-production, the tag would be perma-locked to prevent any tampering.

Out of the cases that were measured in the pilot, 100% of them had their production date successfully set and tags perma-locked. Through this work, Golden State Foods was also able to discover best practices that led to their automated validation checks, allowing for more flexibility with encoding traceability data on the line, with no impact to speed.