Download Preparation for Distribution specifications.

- 2A1_DistributeProductCatalogInformation_V02_00_00

- 2A1_DistributeProductCatalogInformation_V02_01_00

- 2A1_DistributeProductCatalogInformation_V02_02_00

- 2A1_DistributeProductCatalogInformation_V02_03_00

- 2A1_DistributeProductCatalogInformation_V02_04_00

- PIP2A1_V11.00.00_DistributeProductCatalogInformation

- PIP2A1_V11.01.00_DistributeProductCatalogInformation

- 2A3_QueryMarketingInfo_B01.00.00A

- 2A4_QuerySalesPromoRebate_B01.00.00A

- 2A6_QueryProductLifecycle_B01.00.00A

- 2A7_QueryProductDiscontinue_B01.00.00A

- 2A9_QueryECTechnicalInformation_V01_00_00

- 2A9_QueryTechnicalProductInformation_V01_01_00

- 2A9_QueryTechnicalProductInformation_V01_01_01

- 2A10_DistributeDesignEngineeringInformation_V01_00_00

- 2A10_DistributeDesignEngineeringInformation_V02_00_00

- 2A12_DistributeProductMaster_V01_00_00

- 2A12_DistributeProductMaster_V01_01_00

- 2A12_DistributeProductMaster_V01_02_00

- 2A12_DistributeProductMaster_V01_03_00

- PIP2A12_V11.00.00_DistributeProductMaster

- PIP2A13_V11.00.00_DistributeMaterialCompositionInformation

- PIP2A13_V11.01.00_DistributeMaterialCompositionInformation

- PIP2A13_V11.02.00_DistributeMaterialCompositionInformation

- PIP2A13_V11.03.00_DistributeMaterialCompositionInformation

- PIP2A13_V11.04.00_DistributeMaterialCompositionInformation

- PIP2A15_R11.00.00A_RequestMaterialCompositionInformation

- PIP2A16_V11.00.00_DistributeEngineeringInformationInquiry

- PIP2A17_V11.00.00_NotifyOfCertificateOfAnalysis

- PIP2A17_V11.01.00_NotifyOfCertificateOfAnalysis

- PIP2A17_V11.02.00_NotifyOfCertificateOfAnalysis

- PIP2A17_V11.03.00_NotifyOfCertificateOfAnalysis

- PIP2A17_V11.04.00_NotifyOfCertificateOfAnalysis

- PIP2A17_V11.05.00_NotifyOfCertificateOfAnalysis

- PIP2A18_V11.00.00_NotifyOfCertificateOfAnalysisResponse

- PIP2A18_V11.01.00_NotifyOfCertificateOfAnalysisResponse

- Cluster 2, Product Information, enables distribution and periodic update of product and detailed design information, including product change notices and product technical specifications.

- PIPs for Segment 2A, Preparation for Distribution,enables distribution of product resources, including sales catalog and basic technical information, and obtainment of extended product information.

| PIP | Title | Description |

|---|---|---|

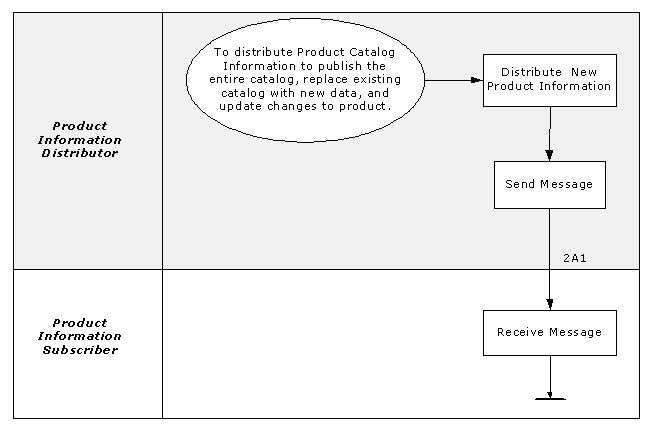

| 2A1 | Distribute New Product Information | Specifies processes for distributing new product information to buyers -- so that enterprise systems can be established to accept product orders -- and for product information users to populate buyers' online sales catalogs. |

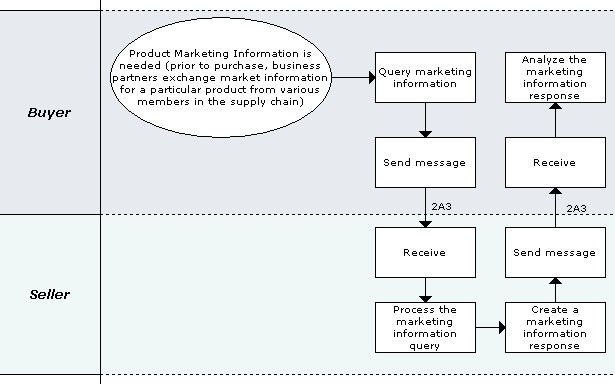

| 2A3 | Query Marketing Information | Provides business partners with a systematic approach to querying and receiving marketing information. |

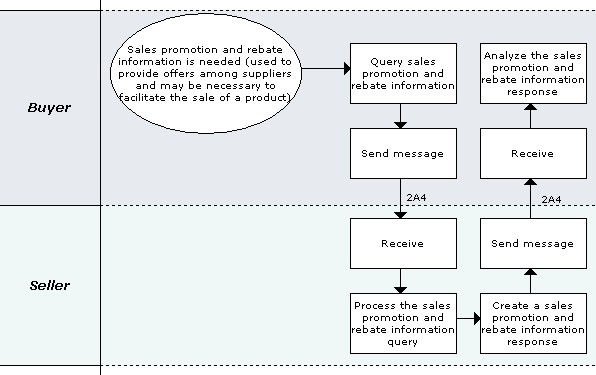

| 2A4 | Query Sales Promotion & Rebate Information | Lets product buyers request sales promotion and rebate information, and allows product sellers to send the information and accept acknowledgement that it was received. |

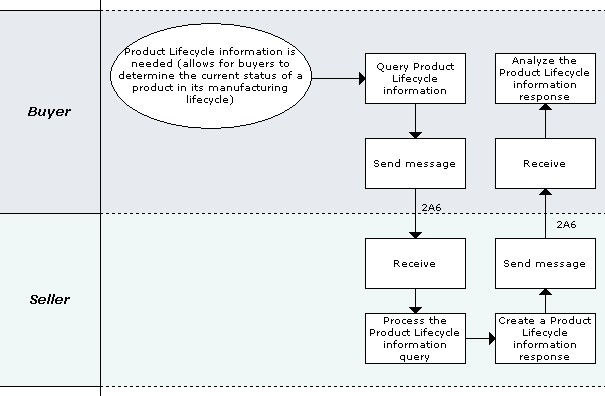

| 2A6 | Query Product Lifecycle Information | Lets product buyers request product lifecycle information, and allows product sellers to send the information and accept acknowledgement that it was received. |

| 2A7 | Query Product Discontinuation Information | Provides partners with the information necessary to discontinue items in their systems. |

| 2A9 | Query Technical Product Information | Specifies the process for querying EC, IT & SM supply chain partners for technical information, including component technical specifications that can be used for business activities such as hosting online electronic catalogs and sales configuration systems. |

| 2A10 | Distribute Design Engineering Information | The Distribute Design Engineering Information PIP enables a standardized provision of information needed by product designers and product engineers during the planning, design, and engineering processes. This information may be provided directly from the product supplier to the product user, or it may be passed via one or more companies in the distribution chain. Thus this PIP also supports the provision of technical information to product databases throughout the distribution chain. |

| 2A12 | Distribute Product Master | The purpose of this PIP is to specify the process for a Product Information Distributor, who is typically a product supplier, to distribute device-level product identification, including family attributes, location specific data, procurement data and limited product lifecycle information, required for the MRP system of a Product Information User, who is typically a product buyer. |

| 2A13 | Distribute Material Composition Information | The purpose of this PIP is to supply requested material composition information for a given product(s). |

| 2A15 | Request Material Composition Information | The purpose of this PIP is to request product information that describes the composition of materials for a product(s). |

| 2A16 | Distribute Engineering Information Inquiry | The purpose of this PIP is to automate the product engineering information exchanges between supply chain partners. |

| 2A17 | Notify of Certificate of Analysis | The purpose of this PIP is to enable the transmission of an accepted standard for certificate of analysis of which the quality or purity of material being shipped is attested. |

| 2A18 | Notify of Certificate of Analysis Response | The purpose of this PIP is to allow the customer to confirm the acceptance or rejection on the certification of the delivered material upon meeting the agreed requirements. |

| 2A1 | Distribute New Product Information |

|---|---|

| Specifies processes for distributing new product information to buyers -- so that enterprise systems can be established to accept product orders -- and for product information users to populate buyers' online sales catalogs. |

Business Process

The "Distribute Product Catalog Information" Partner Interface Process (PIP) enables a buyer to manage the procurement of a specific item from a seller, thereby reducing costs throughout the supply chain by reducing key strokes, errors and the effort to publish & maintain product sales information. The intent of this PIP is used for procurement processes only. Its use will be for sales and marketing purposes. This PIP will also provide the capability to automate the push of product sales information to partners.

Product catalog information will be distributed to a partner in 3 main scenarios:

- To publish a Whole (brand new full) catalog;

- Catalog publisher issues a new catalog with a new ID

- To replace a Whole (existing full catalog) with all new data;

- Catalog publisher replaces a previously issued catalog with a new catalog including a new ID

- To update deltas for an entire product. (not subsets of one block – must update all categories) There will be the capability to send complete or partial load of products with a qualifier to identify the dataset that is sent. Every trading partner manages versions internally, there is no specified standard on when to update the version id for a partial or full replace, and reloads are out of scope.

- Catalog publisher updates certain products in a previously issued catalog with the same ID.

Should this transaction not complete successfully, the requesting partner executes PIP0A1, "Notification of Failure".

| 2A3 | Query Marketing Information |

|---|---|

| Provides business partners with a systematic approach to querying and receiving marketing information. |

Business Process

Prior to purchase, business partners exchange market information for a particular product from various members in the supply chain.

There are numerous points in the supply chain at which product marketing information is necessary. "Product Marketing Information" is a category of information that is necessary to sell or buy the product and does not include the technical specifications of the product.

The RosettaNet Query/Response design pattern allows information to be queried as an XML document and returned as an XML document that is not necessarily tabular in nature (it is often a hierarchical structure).

| 2A4 | Query Sales Promotion & Rebate Information |

|---|---|

| Lets product buyers request sales promotion and rebate information, and allows product sellers to send the information and accept acknowledgement that it was received. |

Business Process

Query Sales Promotion and Rebate Information is used to provide offers among suppliers.

There are numerous points in the supply chain at which Sales Promotion and Rebate Information may be provided. "Product Sales Promotion and Rebate Information" is a category of information that may be necessary to facilitate the sale of a product, and does not include the technical specifications of the product.

The RosettaNet Query/Response design pattern allows information to be requested as an XML document and returned as an XML document that is not necessarily tabular in nature (it is often a hierarchical structure).

| 2A6 | Query Product Lifecycle Information |

|---|---|

| Lets product buyers request product lifecycle information, and allows product sellers to send the information and accept acknowledgement that it was received. |

Business Process

The Query Product Lifecycle Information Partner Interface Process™ (PIP®) allows for buyers to determine the current status of a product in its manufacturing lifecycle.

There are numerous points in the supply chain at which "Product Lifecycle Information" is necessary.Product Lifecycle Information is a category of information that may be necessary to buy the product.

The RosettaNet Query/Response design pattern allows information to be requested as an XML document and returned as an XML document that is not necessarily tabular in nature (it is often a hierarchical structure).

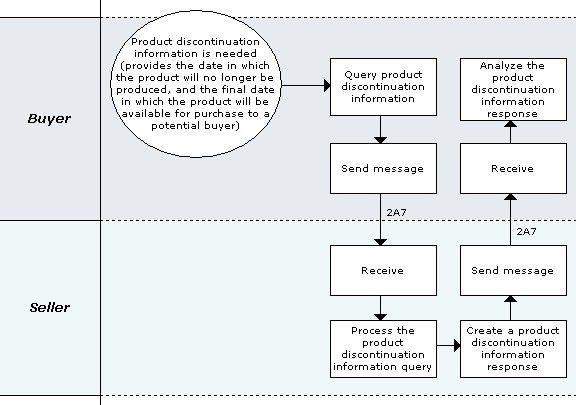

| 2A7 | Query Product Discontinuation Information |

|---|---|

| Provides partners with the information necessary to discontinue items in their systems. |

Business Process

The Query Product Discontinuation Information Partner Interface Process™ (PIP®) provides the date in which the product will no longer be produced, and the final date in which the product will be available for purchase to a potential Buyer.

There are numerous points in the supply chain at which Product Discontinuation Information is necessary.Product Discontinuation Information is a category of information that may be necessary to buy the product.

The RosettaNet Query/Response design pattern allows information to be requested as an XML document and returned as an XML document that is not necessary tabular in nature (it is often a hierarchical structure).

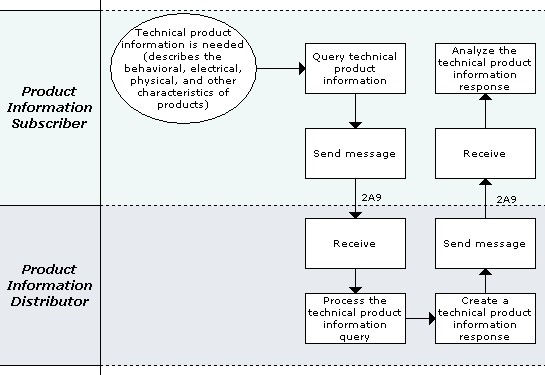

| 2A9 | Query Technical Product Information |

|---|---|

| Specifies the process for querying EC, IT & SM supply chain partners for technical information, including component technical specifications that can be used for business activities such as hosting online electronic catalogs and sales configuration systems. |

Business Process

Technical product information is that category of information that describes the behavioral, electrical, physical, and other characteristics of products. There are numerous classes of customers within the supply chain that need to be able to access product technical information. These include distributors, information providers (such as web portal companies, other commercial information aggregators, and end-customer information system owners), engineering, design engineering, and manufacturing and test engineering.

Depending on the phase of the design cycle, different subsets of the overall set of characteristic information are required, as may be the manner in which that information is requested. Requirements for this PIP(tm) span across many phases of the information life cycle. For example, the design of printed circuit assemblies (PCA) by original equipment manufacturers (OEM) includes the following lifecycle phases:

Find - OEM companies identify product(s) that match essential needs without knowledge of product identifier, and possibly by search across many potential ProductInformationDistributors (Distributors).

Try - OEM companies evaluate potential selections of information (such as datasheets, models, test benches, packaging options, etc.) for fit to design problem.

Buy - Pricing, availability, risk assessment information, lifecycle data, and sample parts availability are important in this phase.

Design - OEM companies perform design using the selected product. For this phase, EDA libraries and various models are of particular importance.

Build - OEM companies actually build and test the printed circuit assembly and thus, require test patterns and setup conditions, physical information to pick and place the product, and alternate source information, etc.

There is a broad set of product information this PIP® must support. This information can be organized into the following categories:

1. Characteristics - physical, electrical, behavioral, or other characteristics of the product that are described as simple name/value pairs (such as supply voltage, rise delay, package type, etc.) Each of these Characteristics is specified in the RosettaNet Technical Dictionary (Dictionary) with its:

definition, symbol (e.g. Vdd, TRise, etc.),

data type (integer, binary, string, etc.) or value code list (e.g. 1=DIP, 2=SIP, ...),

unit of measure (e.g. volts, seconds, etc.), and

dependent conditions (environmental or test environment under which the characteristic property is specified).

2. CharacteristicSets - multiple characteristics that can be requested with a single name (e.g. RiskAssessment) with semantics defined in the Dictionary. Standardized sets of characteristics are defined by PropertyDefinitionSets in the Dictionary, however, a Distributor may include definitions of its own Sets referenced in a particular message.

3. ProductInformationObjects - standalone files that describe product information as complex structures. Metadata for PIOs are also defined in the Dictionary. A PIO may have any content (defined by its specification), including binary. Some PIOs may also be XML with their own DTDs. Typical product information objects include, but are not limited to:

VHDL or Verilog model: a description of the product's behavior (IEEE standard ASCII format);

TDML instance: a description of timing diagrams for the product (Si2 XML defined ASCII format);

ECPinMap: a description of the product's physical to symbolic pin mapping and other characteristics required to produce a schematic symbol (Si2 XML defined ASCII format);

ECPackage: a description of the product's physical/mechanical characteristics and features for EDA place and route tools (Si2 XML defined ASCII format);

Datasheet: a complete description of the product that can be rendered in human readable format (typically Adobe PDF format);

Table of Contents (TOC): a list of available ProductInformationObjects and CharacteristicSets for the specified product (Si2 XML defined ASCII format).

This PIP(tm) is the most complex in the RosettaNet environment. The semantic for this PIP are actually in two separate but interactive elements. The first is thee RNTD which is the "dictionary where the product classes and their associated characteristics are conformed and resident. The second is a Registry which houses the identity of partners along with their URLS' service capabilities as well as their sourcing capabilities. For a more thorough understanding of the functioning of this PIP, a Product Technical Information Document that explains further can be accessed here. For complete understanding the Technical Product Information Exchange Protocol document and the RNTD Development portion of the Rosettanet Website.

Should this transaction not complete successfully, the requesting partner executes PIP0A1, "Notification of Failure".

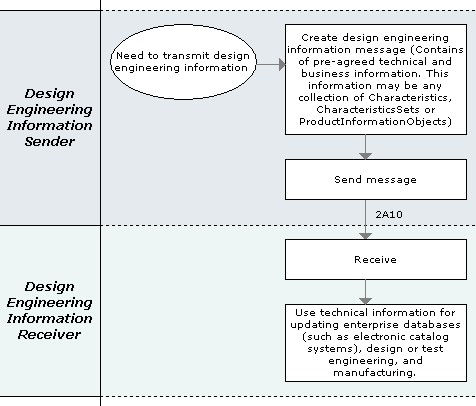

| 2A10 | Distribute Design Engineering Information |

|---|---|

| The Distribute Design Engineering Information PIP enables a standardized provision of information needed by product designers and product engineers during the planning, design, and engineering processes. This information may be provided directly from the product supplier to the product user, or it may be passed via one or more companies in the distribution chain. Thus this PIP also supports the provision of technical information to product databases throughout the distribution chain. |

Business Process

Design engineering information is either information that describes the behavioral, electrical, physical, and other characteristics of products or business information related to those products that influences design decisions. There are numerous classes of customers within the supply chain that need to be able to either provide or access design engineering information. These include distributors, information providers (such as web portal companies, other commercial information aggregators, and end-customer information system owners), engineering, design engineering, and manufacturing and test engineering.

Depending on the phase of the design cycle, different subsets of the overall set of characteristic information or business information are required, as may be the manner in which that information is provided. This implies that the PIP® must be asynchronous and that the information for a single product or technology may be delivered in several different batches at different times and that the information may be in many different formats. Some of this information may be proprietary and confidential; thus there will be times when encryption and non-repudiation may be required. Requirements for this PIP also span across many phases of the information life cycle. For example, the design of printed circuit assemblies (PCA) by original equipment manufacturers (OEM) includes the following lifecycle phases:

- Find - OEM companies identify product(s) that match essential needs or track the development process for key products or technologies to be used in new product designs. This step usually involves creating a short list of potential products/technologies.

- Try - OEM companies evaluate potential selections of information (such as datasheets, models, test benches, packaging options, etc.) for fit to design problem. This involves more mining of technical and business information.

- Buy samples - Pricing, availability, risk assessment information, lifecycle data, and sample parts availability are important in this phase.

- Design - OEM companies perform design using the selected product. For this phase, EDA libraries and various models are of particular importance.

- Build prototype - OEM companies actually build and test the printed circuit assembly and thus, require test patterns and setup conditions, physical information to pick and place the product, and alternate source information, etc.

This PIP provides significant value across the entire supply chain by giving information customers a consistent, implementation-independent method to receive the information that they need for their business process when they need it, and receive it in a computer sensible format. This can significantly reduce the cost of acquiring information manually from different information distributor websites in formats that are only human readable. Receiving the information in a computer sensible format (with semantics defined to a fine level of granularity) allows the data to be translated to internal databases, EDA libraries, and human-readable renditions, by software automation. Thus the need for re-keying data – and the resulting errors, time, and expense – is eliminated.

Should this transaction not complete successfully, the requesting partner executes PIP0A1, "Notification of Failure".

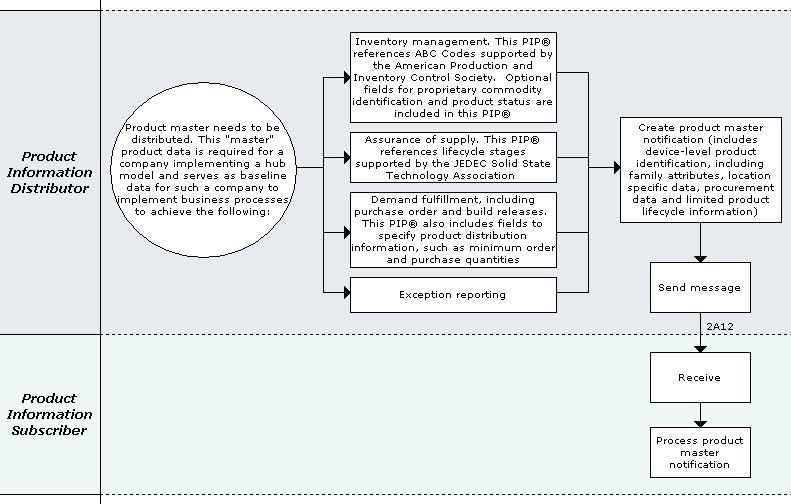

| 2A12 | Distribute Product Master |

|---|---|

| The purpose of this PIP is to specify the process for a Product Information Distributor, who is typically a product supplier, to distribute device-level product identification, including family attributes, location specific data, procurement data and limited product lifecycle information, required for the MRP system of a Product Information User, who is typically a product buyer. |

Business Process

Large Manufacturing Resource Planning (MRP) systems provide complex capabilities for automating the selection of suppliers from a previously identified list, based on inventory importance, product lead-times and lifecycle information. Product identification at the family attribute level may also be required to support the selection of alternative, but similar devices to support the product buyer's performance and build schedule requirements. Typically, this requires the collection and maintenance of data, which is used by the MRP system to generate purchase order releases, schedule data changes and cancellations.

This "master" product data is required for a company implementing a hub model and serves as baseline data for such a company to implement business processes to achieve the following:

- Inventory management. This PIP® references ABC Codes supported by the American Production and Inventory Control Society (see http://www.apics.org for more information).Optional fields for proprietary commodity identification and product status are included in this PIP®.

- Assurance of supply. This PIP® references lifecycle stages supported by the JEDEC Solid State Technology Association (see http://www.jedec.org for more information).

- Demand fulfillment, including purchase order and build releases.This PIP® also includes fields to specify product distribution information, such as minimum order and purchase quantities.

- Exception reporting.The hub owner must address the technical capability for product data to be accessed securely among partners.Such security access must also be addressed in the Trading Partner Agreement (TPA).

Other TPA terms should include the mechanics and timing for database population, refresh and obsolete product disposition.

Should this transaction not complete successfully, the requesting partner executes PIP0A1, "Notification of Failure".

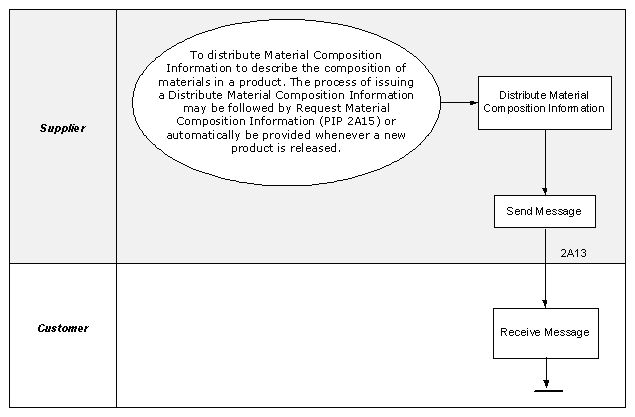

| 2A13 | Distribute Material Composition Information |

|---|---|

| The purpose of this PIP is to supply requested material composition information for a given product(s). |

Business Process

The "Distribute Material Composition Information" Partner Interface Process (PIP) is focused on gathering product information that describes the composition of materials in the products. The main drivers for collecting this type of material composition information are due to legal requirements, market requirements for the industry to proactively report this information in their designs.

The process includes the following steps:

- The customer needs to know based on legal or market requirements the materials composition of a purchased product that might be included or are included in his design

- The customer defines the demands and defines the material composition information that is needed. The information needed might be based on guidelines decided by industry and/or based on a agreements.

- The customer makes an agreement with their supplier to provide a material composition information exchange based on a guideline decided by a industry and/or individually. The timing for this agreement differs between companies and thus out of scope for this milestone.

- The customer requests the agreed information from his supplier. The timing for this request differs between companies (e.g., to automatically be provided whenever a new product is released or to be provided only when the customer specifically requests it) and thus the timing of this request is out of scope for this milestone.

- The supplier might have requested this information to be available on demand.

- If the information is available in-house the supplier sends the requested information to his customer.

- If the supplier needs to gather some or all of the requested information he uses the same business process as his customer. See items #2.- #4. When all required information is gathered, the supplier compiles the information and sends the requested information to his customer. Compilation or aggregation of in-house information will be done by the supplier’s backend system and are out of the scope of this e-business process.

- The customer receives the information. The customer might store the information in his in-house backend system to be able to provide his customer in his turn with compiled information. Storing and compiling in-house information will be done by customer backend systems and are out of the scope of this e-business process.

Should this transaction not complete successfully, the requesting partner executes PIP0A1, "Notification of Failure".

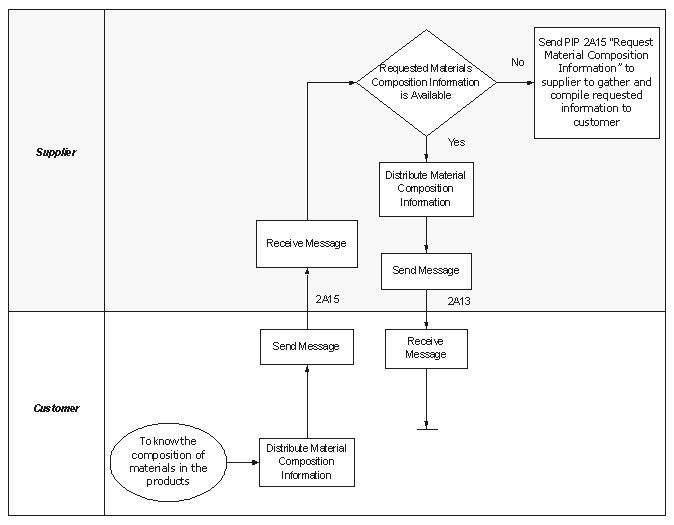

| 2A15 | Request Material Composition Information |

|---|---|

| The purpose of this PIP is to request product information that describes the composition of materials for a product(s). |

Business Process

The "Request Material Composition Information" Partner Interface Process (PIP) is focused on requesting for product information that describes the composition of materials in the products. The main drivers for collecting this type of material composition information are due to legal requirements, market requirements for the industry to proactively report this information in their designs.

The process includes the following steps:

- The customer needs to know based on legal or market requirements the materials composition of a purchased product that might be included or are included in his design.

- The customer defines the demands and defines the material composition information that is needed. The information needed might be based on guidelines decided by industry and/or based on a agreements.

- The customer makes an agreement with their supplier to provide a material composition information exchange based on a guideline decided by a industry and/or individually. The timing for this agreement differs between companies and thus out of scope for this milestone.

- The customer requests the agreed information from his supplier. The timing for this request differs between companies (e.g., to automatically be provided whenever a new product is released or to be provided only when the customer specifically requests it) and thus the timing of this request is out of scope for this milestone.

- The supplier might have requested this information to be available on demand.

- If the information is available in-house the supplier sends the requested information to his customer.

- If the supplier needs to gather some or all of the requested information he uses the same business process as his customer. The customer send the request to obtain the information , the supplier compiles the information and sends the requested information to his customer. Compilation or aggregation of in-house information will be done by the supplier’s backend system and are out of the scope of this e-business process.

- The customer receives the information. The customer might store the information in his in-house backend system to be able to provide his customer in his turn with compiled information. Storing and compiling in-house information will be done by customer backend systems and are out of the scope of this e-business process.

Should this transaction not complete successfully, the requesting partner executes PIP0A1, "Notification of Failure".

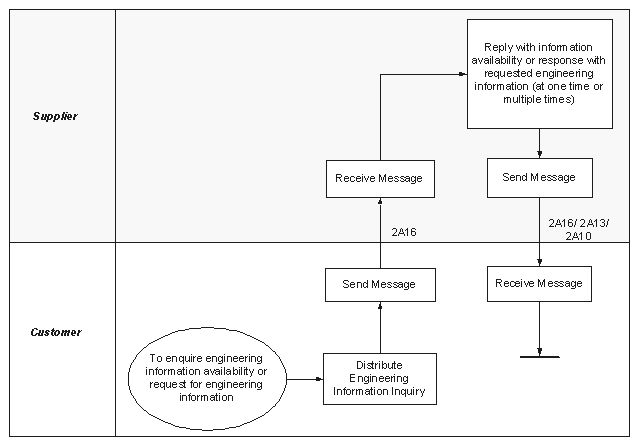

| 2A16 | Distribute Engineering Information Inquiry |

|---|---|

| The purpose of this PIP is to automate the product engineering information exchanges between supply chain partners. |

Business Process

The engineering information exchange process is initiated during the electric/electronics part selection for OEM products. Generally, after the initial research is completed, the product design engineer and/or procurement engineer must secure information from the part supplier for very detailed design engineering information on the part. The current process utilizes email, fax, phone or a request form to collect information. If the supplier does not have information on hand, then the supplier replies with when the information will be available and an estimated due date for when the information can be distributed (which is for most cases).

The initial request from the customer may be traced until the request has been completed or canceled. In some cases, the customer does not place a request after receiving the initial reply of the distribution schedule from the supplier (related to unsatisfactory delivery timing for the product information).

The following tasks are supported within the Engineering Information business process:

- Inquiry for engineering information (Query)

- Reply with information availability (Response)

- Request for engineering information (Request)

- Response with requested engineering information (Response)

Should this transaction not complete successfully, the requesting partner executes PIP0A1, "Notification of Failure".

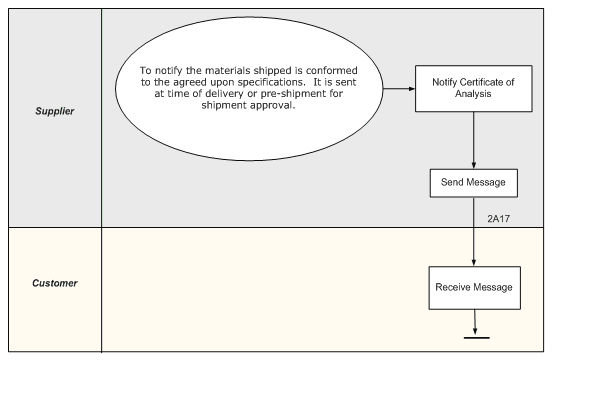

| 2A17 | Notify of Certificate of Analysis |

|---|---|

| The purpose of this PIP is to enable the transmission of an accepted standard for certificate of analysis of which the quality or purity of material being shipped is attested. |

Business Process

PIP 2A17 Business Process Description

Certificate of Analysis is a document attesting to the quality or purity of the material being shipped. The origin of certificate of analysis may be the manufacturer of the material, the distributor, or another third party, such as an inspection firm or independent laboratory. In most cases the document is created by the manufacturer and certifies that the material shipped has been tested on his facility and found to conform to the agreed upon specifications. It is provided at the time of delivery, but may be provided prior to delivery to allow pre-shipment approval. A certificate of analysis is used in several industries including, but not limited to, electronic, chemical, industrial gas, petrochemical, textile, etc.

Should this transaction not complete successfully, the requesting partner executes PIP0A1, "Notification of Failure".

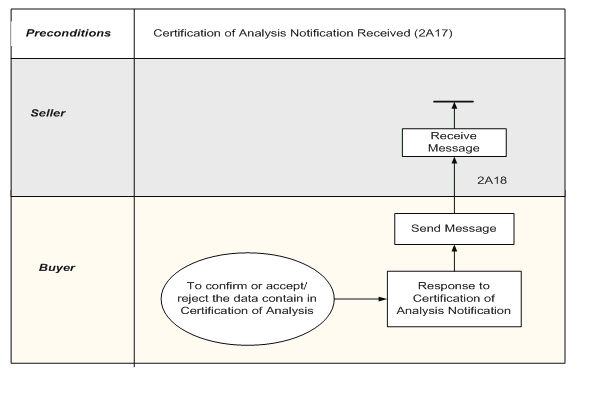

| 2A18 | Notify of Certificate of Analysis Response |

|---|---|

| The purpose of this PIP is to allow the customer to confirm the acceptance or rejection on the certification of the delivered material upon meeting the agreed requirements. |

Business Process

PIP 2A18 Business Process Description

The recipient of PIP 2A17 "Notify of Certificate of Analysis" may respond with this PIP 2A18, "Notify of Certificate of Analysis Response" as the confirmation message. The origin of the certificate of analysis may be the manufacturer of the material, the distributor, or another third party, such as an inspection firm or independent laboratory. In most cases the document is created by the manufacturer and certifies that the material shipped has been tested in his facility and found to conform to the agreed upon specifications. The certificate of analysis details the test methods and results obtained for the specific material and package being supplied.

Should this transaction not complete successfully, the requesting partner executes PIP0A1, "Notification of Failure".