-

What was your inspiration for starting Ship Bottom Brewery?

Ship Bottom Brewery started out as a hobby in my garage in 1995. A lot of brewers start out that way, just doing it for fun and then it transitions into a business. As my interest in brewing grew and the beer was getting better, I started to improve the process of making the beer, which included temperature control and computer automation of the system. I was making more beer than I could drink, and friends started saying things like, "Wow, you should really try to do something with this." So got a license to operate from Pennsylvania in 2012. After we would go to beer festivals, we started noticing more and more people following us on social media. We started to grow a following for our brand. At that point we couldn't keep up with demand. Today we have a brewery in Beach Haven, NJ and a Beer Garden in Ambler, PA.

When did you know you were ready to quit your corporate job and go full time at Ship Bottom Brewery?

When I started the brewery down in Beach Haven, New Jersey, I was working two jobs. I worked in IT Sales for about 25 years. In 2018, business really started to ramp up and it was impossible to have both jobs. I decided to quit my full-time job, once I thought I'd actually make money doing this. I’ve been running this business full time since 2018 and it’s been great.

What channels do you sell your products through?

We sell both direct and through distributors. We have our beer in 16 counties in New Jersey. We sell in Southeastern Pennsylvania, mostly in the Philadelphia area and surrounding counties. In New Jersey we self-distribute. We’re still building out and evolving. We have spaces for cold storage now, we have a fleet of trucks, drivers, logistics managers to plan the days and get the deliveries out. In Pennsylvania we use a wholesaler to get our product out in mass.

Where did you go to learn about how to run your business?

I think it's trial by fire, and we learn every day. The best thing we can do is learning from mistakes and changing things. The market is constantly evolving, and people aren’t as loyal as they used to be. We need innovate regularly.

What’s your most popular product?

Our fastest selling beers is one of our originals, The Shack IPA. It was named after a duck hunting shack, which was a local landmark. Unfortunately, it was destroyed during Hurricane Sandy. You could see it from the bridge, when you're driving on to the island. We wanted to have a memorial to that special landmark. It’s always been a part of who we are to keep close ties to our community.

Why did you choose GS1 US for barcodes?

I saw that the barcode was a necessity right away. I researched what companies to use for barcodes. Out of everything I read, I felt like GS1 US was the top, trusted organization that we could use. If I didn’t have a barcode in hand when I went to distributors, I believe they would say, "Just get a barcode and come back." When we first started thinking about packaging, I went into store and looked at how they were selling the products and questioned them on what they needed. One of the main things was a barcode. I knew right away I needed one and I had to get that on all of our packaging. I’ve had barcodes since we started packaging out of our production brewery in 2016.

Do you use GS1 US Data Hub | Product® to manage your data?

Yes, Data Hub is very simple to use and it's great because it's at my fingertips. I didn’t even need to use the training that is available. I’ve been able to go in there on the fly and create barcodes. I’ve been able to create the barcodes that I need for cans and packages every time. I input the product data and Data Hub spits out the barcode to me as a JPEG. I’m able to get the image to the company that makes our packaging for our products, and we'll go to market with that right away. I was on vacation in Puerto Rico and was able to get a barcode for a new product over to packaging company without any hassle!

How did COVID-19 impact your business strategy for 2020?

COVID threw us for a loop. We had to change the way we did business overnight. We offered curbside pickup at our main production facility in Beach Haven, New Jersey, and at our small nano brewery out of my garage. We started offering home delivery services throughout the beach and also in Southeastern Pennsylvania. We had to change our focus from draft beer to canned. Previously, we were very focused on draft beer and all of the sudden, it flipped. Now we’re about 90 percent packaged goods, compared to 10 percent draft beer.

What’s your advice for other small businesses?

Have a business plan in place and know your market. Always know what’s going on inside your market, look for trends and make sure you never fall behind on what’s new in your area. The industry is always changing, and you have to learn how to adapt. Have a good crew, and a team you trust. Empower them.

Small Business Spotlight

Explore Member Growth Stories

-

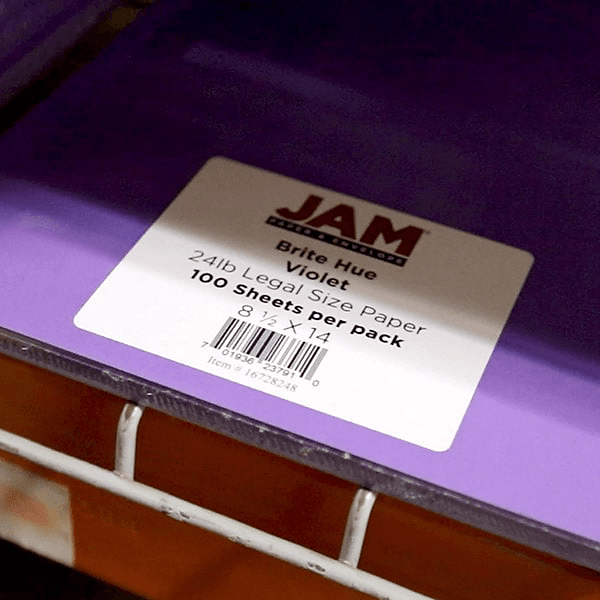

JAM Paper

Family owned and operated since 1955, JAM Paper & Envelope offers a wide range of distinctly colorful paper products.